ChronoCut function

Improvement of processing capability

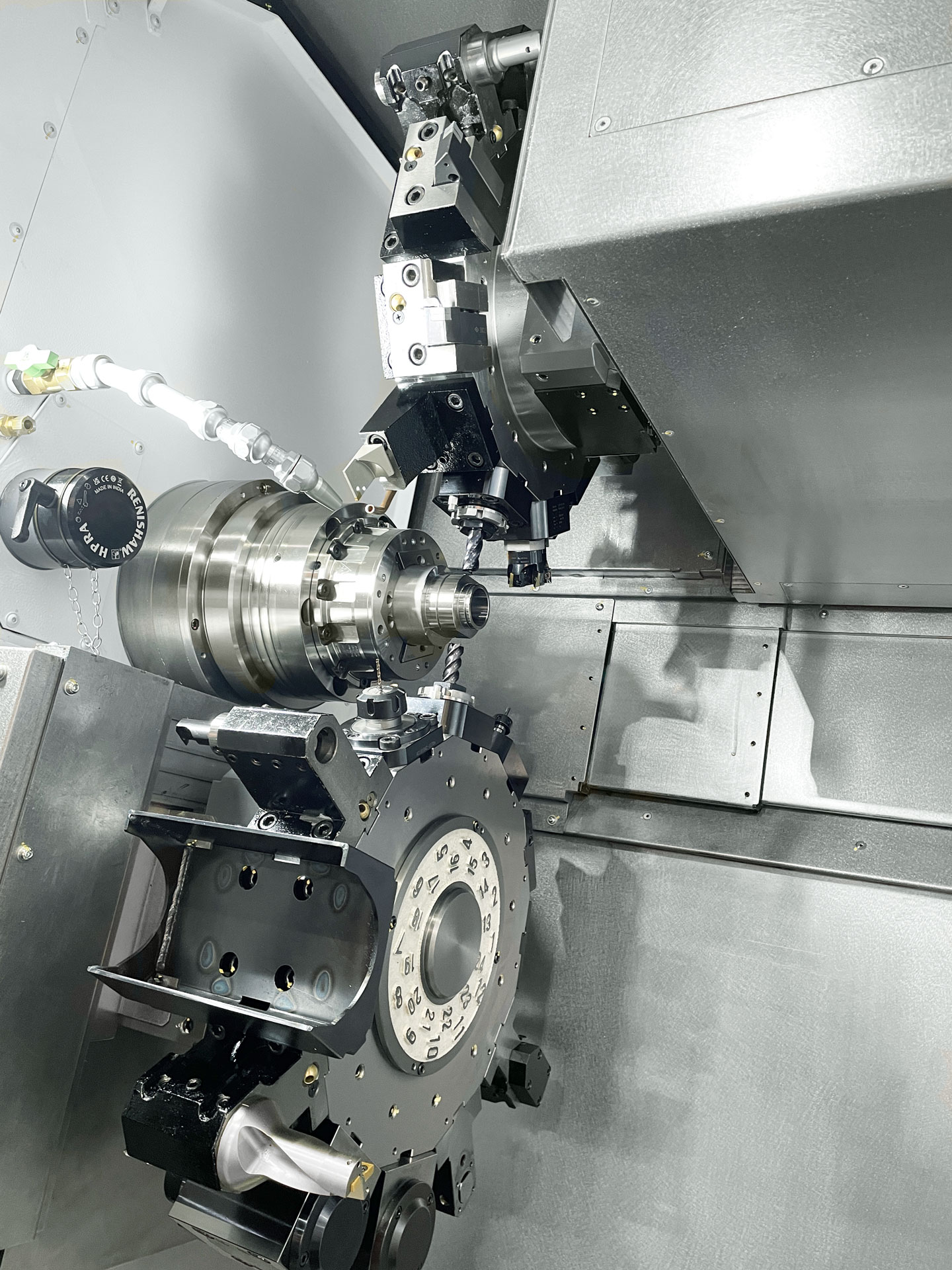

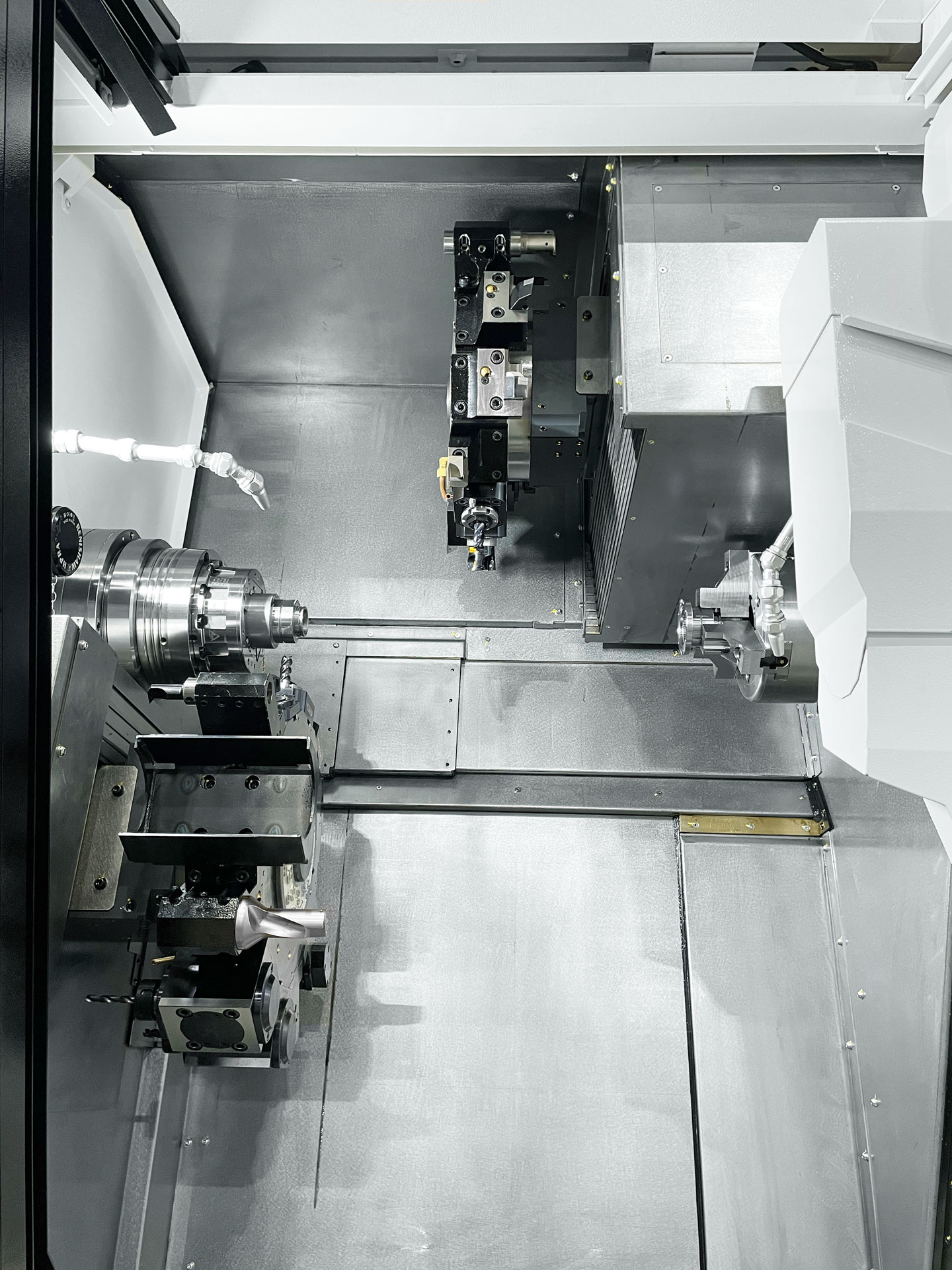

Standard Y-axis double turret and opposing dual spindle compound machining machine

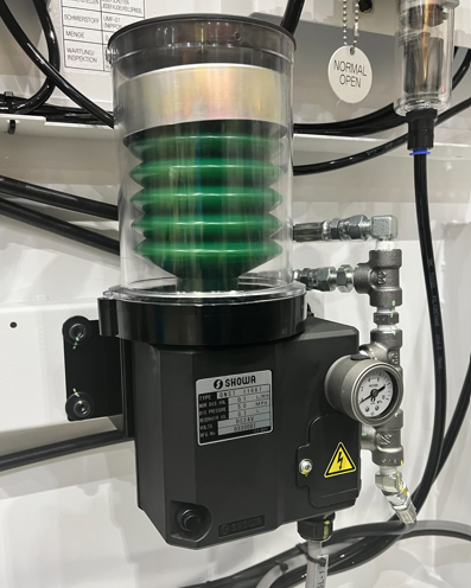

Full axis grease lubrication significantly reduces the amount of oil used

Nakamura's unique features can shorten the idle time of equipment. This is a brand new software and control technology,

To solve the problem of idle equipment during the processing. When using this function, the machining conditions remain unchanged, so it will not affect the product accuracy.

WY-150V is the first model in this class that can choose a spindle with a diameter of 80 bar capacity, and can be equipped with a maximum of 28/15kW powerful motor.

The standard milling motor has a power of 7.5/3.7kW and a maximum speed of up to 10000 revolutions per minute.

In this way, even large diameter workpieces can be processed quickly while maintaining high rigidity and precision.

Standard Y-axis double turret

Up to 48 cutting tools can be equipped

Opposite dual spindle, simultaneous processing on both sides, reducing processing time

Due to the use of grease lubrication type, the lubrication frequency has been significantly reduced, and the running time of the machine has been improved.

In addition, the consumption of oil has also been reduced, which is an environmentally friendly design.